How To Repair A Leaky Copper Pipe

How to Repair a Leaking Copper Piping

v simple steps to repair a leak

You tin fix leaky copper pipe quickly and efficiently with special repair sleeves. We show you how to cutting and solder copper supply lines.

You might likewise similar: TBD

- Time

- Complexity

- Price

- A full day

- Intermediate

- Less than $20

Cut out the old pipe and solder in a new coupling

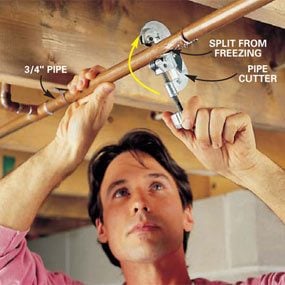

When a copper water pipe corrodes and leaks, or bursts from freezing, you lot take to set it fast. If the leak is pinhole-sized and less than 1/ii in. of pipe must be removed, you can brand the repair by cut the pipage and soldering ("sweating") on an ordinary pipe coupling.

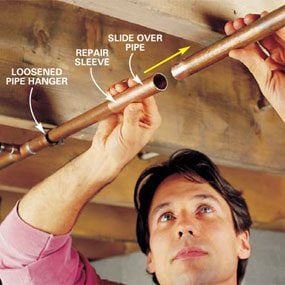

But to repair longer sections, use a "sweat" coupling, which you tin discover at home centers and well-stocked hardware stores. You lot can buy a sweat coupling sized to repair 1/2-in. or 3/4-in. copper piping. Marker the leak, shut off the main h2o valve and bleed (or thaw and drain) the affected pipe. Cutting out the damaged section (Photo i), then mensurate the gap and, from the sweat coupling, cut a repair piece that's one in. longer than the damaged section.

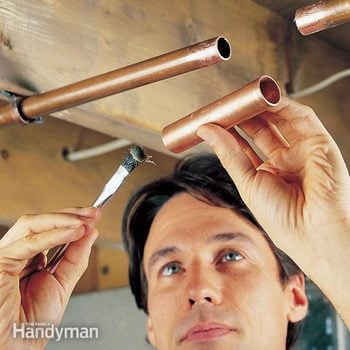

The key to a good solder joint is to keep the inside of the pipes dry, so go on a cotton rag stuffed in each pipe end to blot dribbles of water until just before you solder. Open a faucet above that level to keep pressure from building upwards and dribbling more than h2o into your repair. Then complete the steps shown in Photos 2 – iv for a leak-proof repair. Once finished, plough the main supply valve on and check for leaks.

Sweat coupling and tubing cutter

Cut the repair sleeve from the 12-in. repair coupling stock. Shine the crude-cut inside edges of the sleeve by inserting the bract of the piping cutter into the cut ends and turning the cutter until the sleeve volition slide over the piping ends without snagging. Clean the sleeve'south inside edges for soldering with a iii/four-in. dia. wire plumbing fixtures brush.

Required Tools for this Pipe Repair Projection

Have the necessary tools for this DIY project lined upwards before you get-go—yous'll save time and frustration.

Propane torch

Required Materials for this Pipage Repair Project

Avoid final-infinitesimal shopping trips past having all your materials ready ahead of time. Hither'due south a list.

Source: https://www.familyhandyman.com/project/how-to-repair-a-leaking-copper-pipe/

Posted by: longtraccivo.blogspot.com

0 Response to "How To Repair A Leaky Copper Pipe"

Post a Comment